Material Handling

Material Handling Systems utilize resources to move entities from one location to another. While material handling systems are not uncommon in service systems, their main use is in manufacturing systems. Material Handling frequently accounts for the majority of the production activity. On the average 50% of companies’ operation costs are composed of material handling costs. Given the impact of material handling on productivity and operation costs, it is crucial that material handling decisions are based on sound principles and practices.

Material handling systems are traditionally classified into one of the following categories :

- Conveyors

- Industrial Vehicles

- Automatic Guides Systems

- Robots

Simulation software can easily represent them, integrated with manufacturing processes, allowing detailed analysis on determining number of systems resources, material inventory and systems performance.

Simulation software can help decrease the number of touches by operators and optimize the movement in a material handling system. It can increase picks/day and pick accuracy. Our 3D simulation packages are ideal for simulating material handling environments. The 3D nature of the software helps identify and solve problems within the nuisances of material handling.

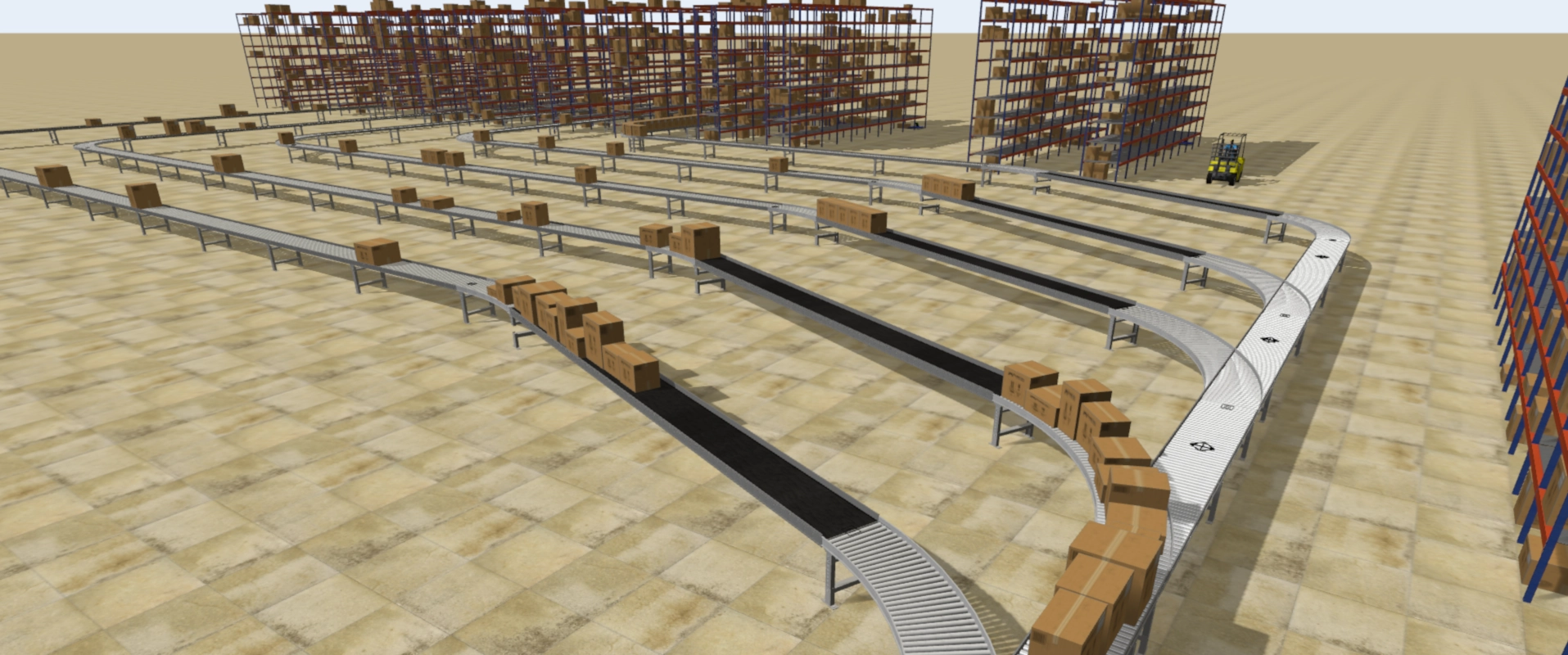

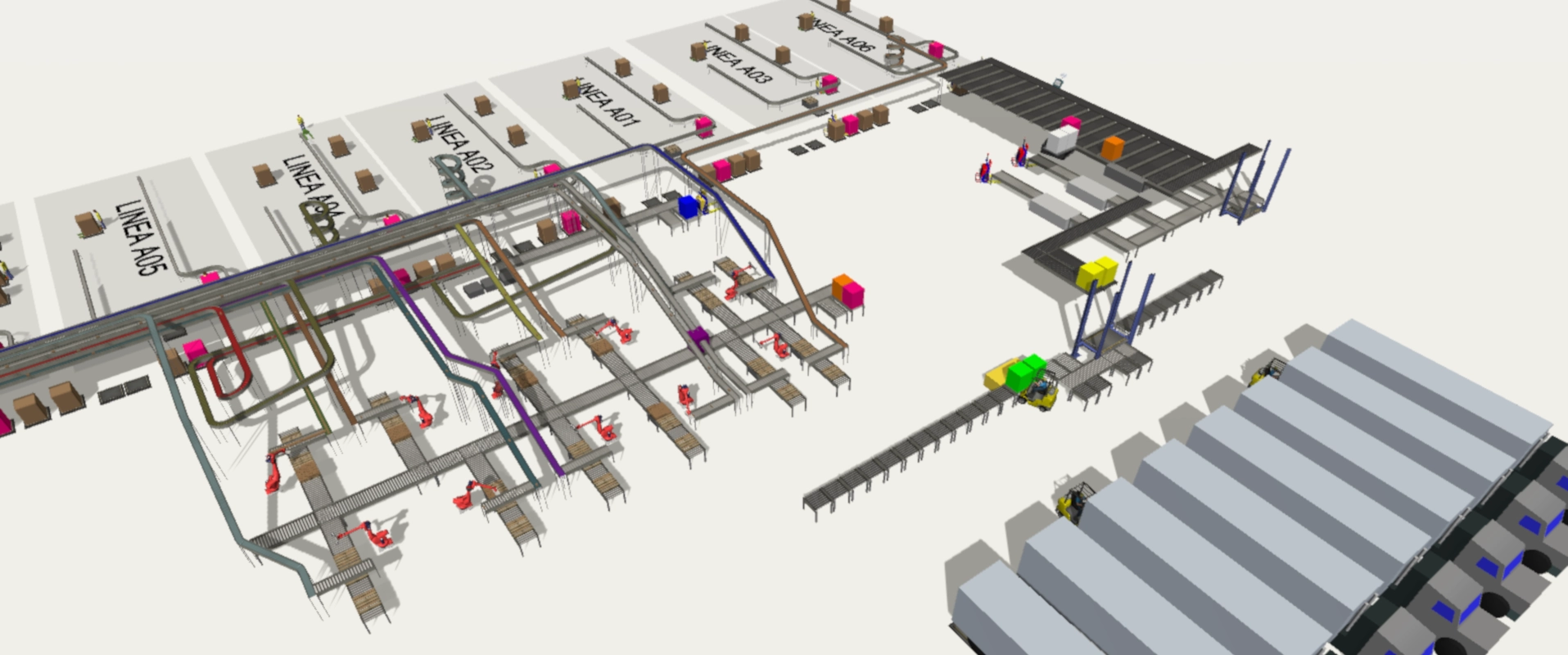

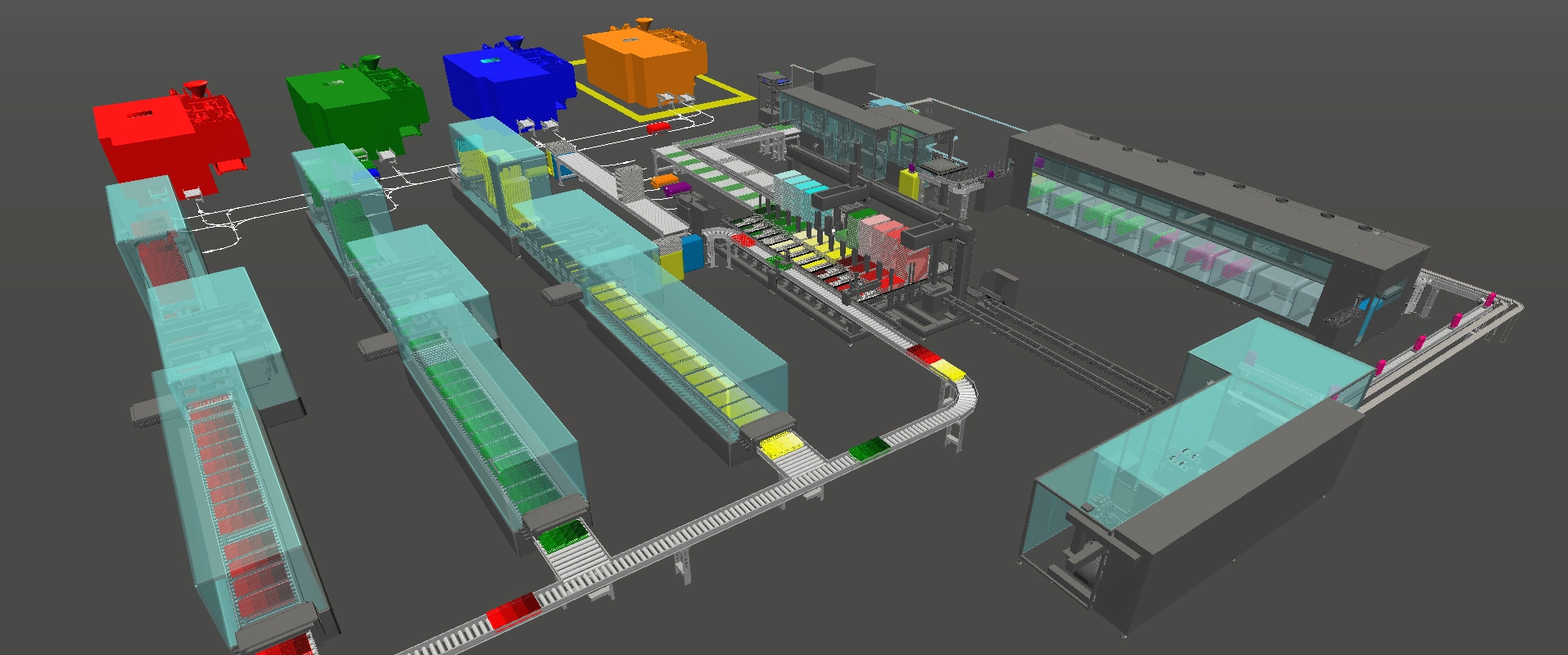

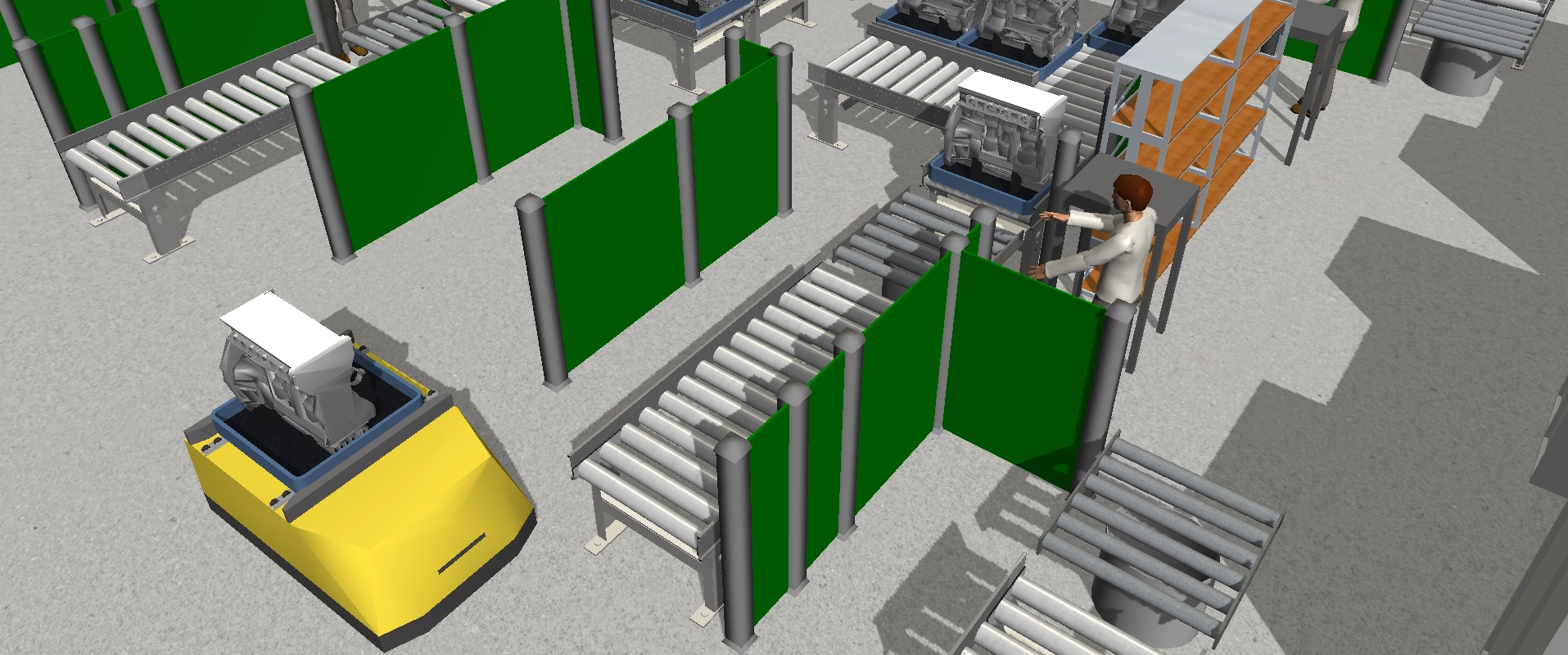

Conveyor Simulation

Simulation software is the best choice for modeling large, complex material handling, manufacturing, and automation systems. We’ve leveraged the latest technology for faster and more impressive 3D simulations, and we’re committed to regular development and updates based on customer feedback.

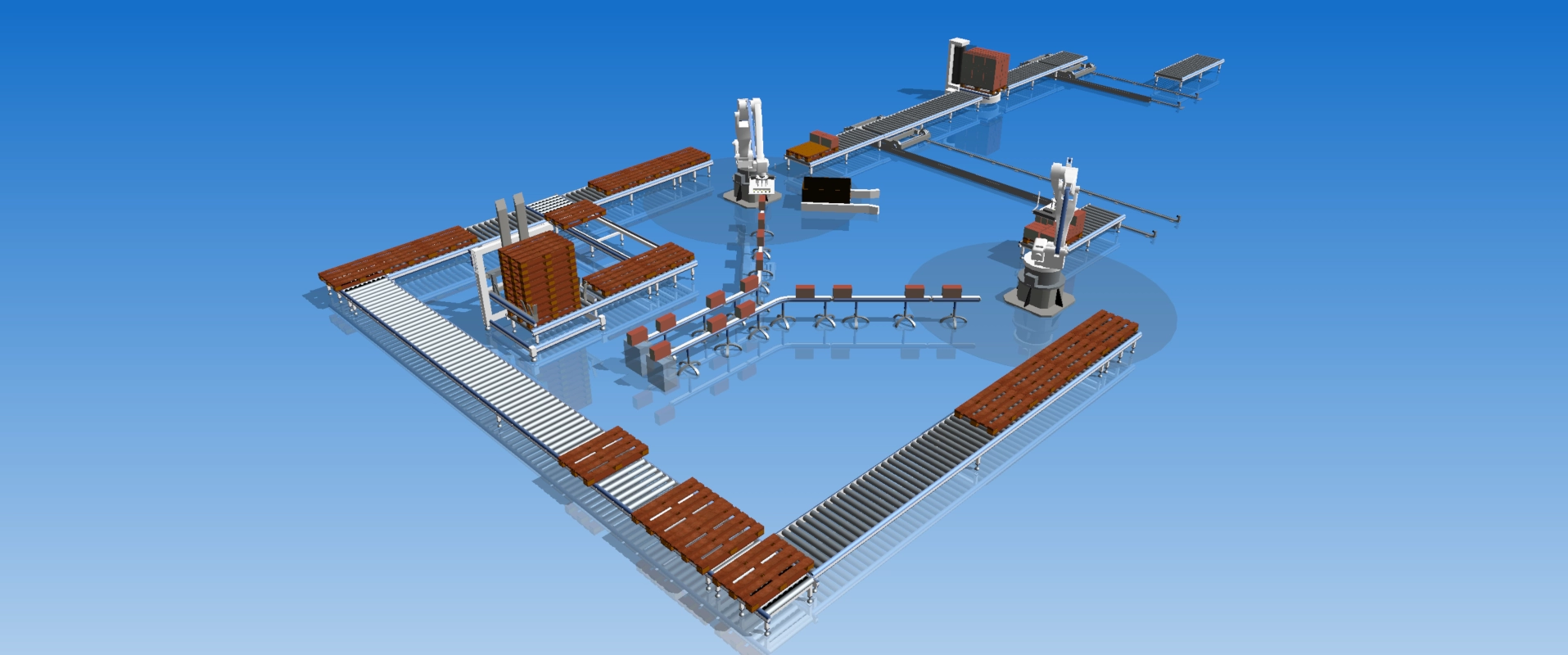

Industrial Vehicles Simulation

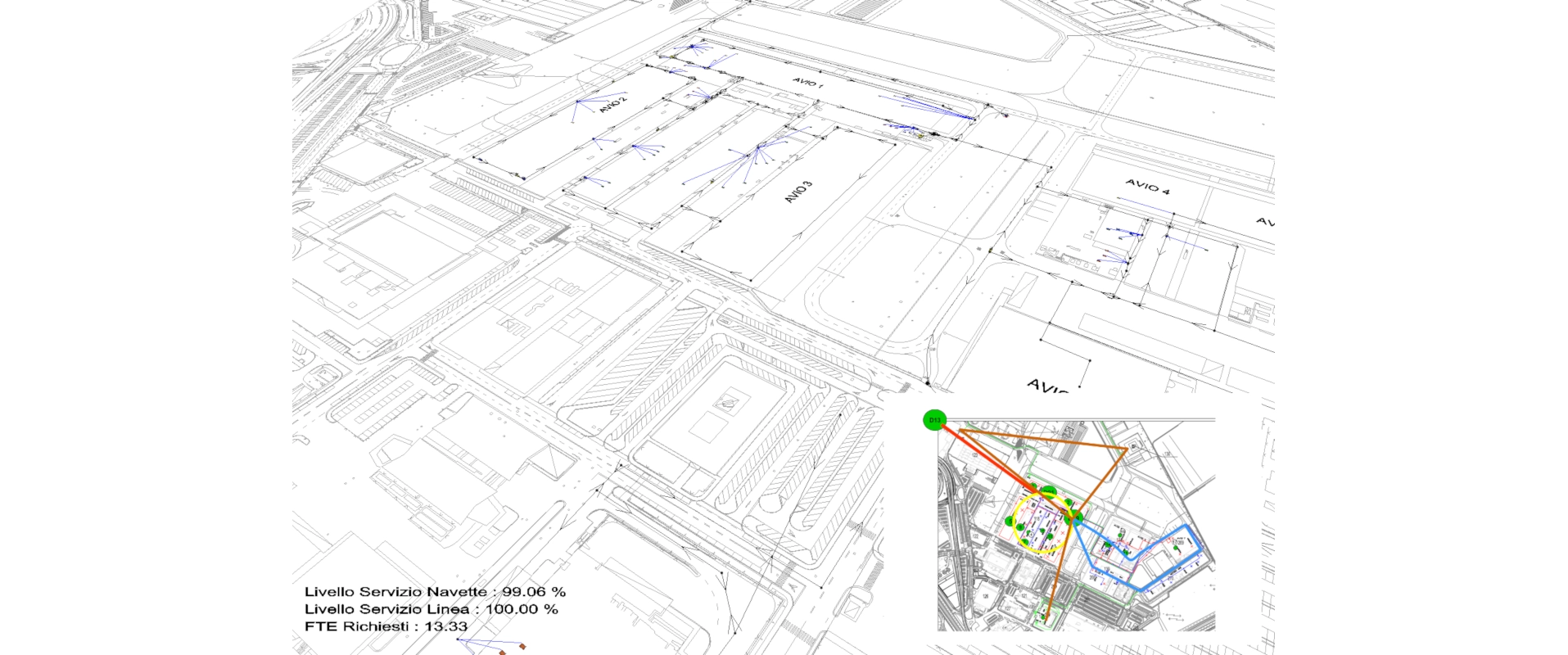

Modeling an industrial vehicle involves modeling a resource that moves along a path network. Path are typically open aisle and spaces in which bi-directional movement is possible and passing is permitted. We provide simulation tools that quickly build these handling systems, providing standard objects such as Shuttle, Forklift, Operator, Elevator, AS/RS, Trucks, Cart. They can moved either along fixed paths or in open areas, taking into account of collision and move preferences. It also possible define complex work strategies like assignment priorities and preemptions, coordination constrains and any type of shifting and breaks.

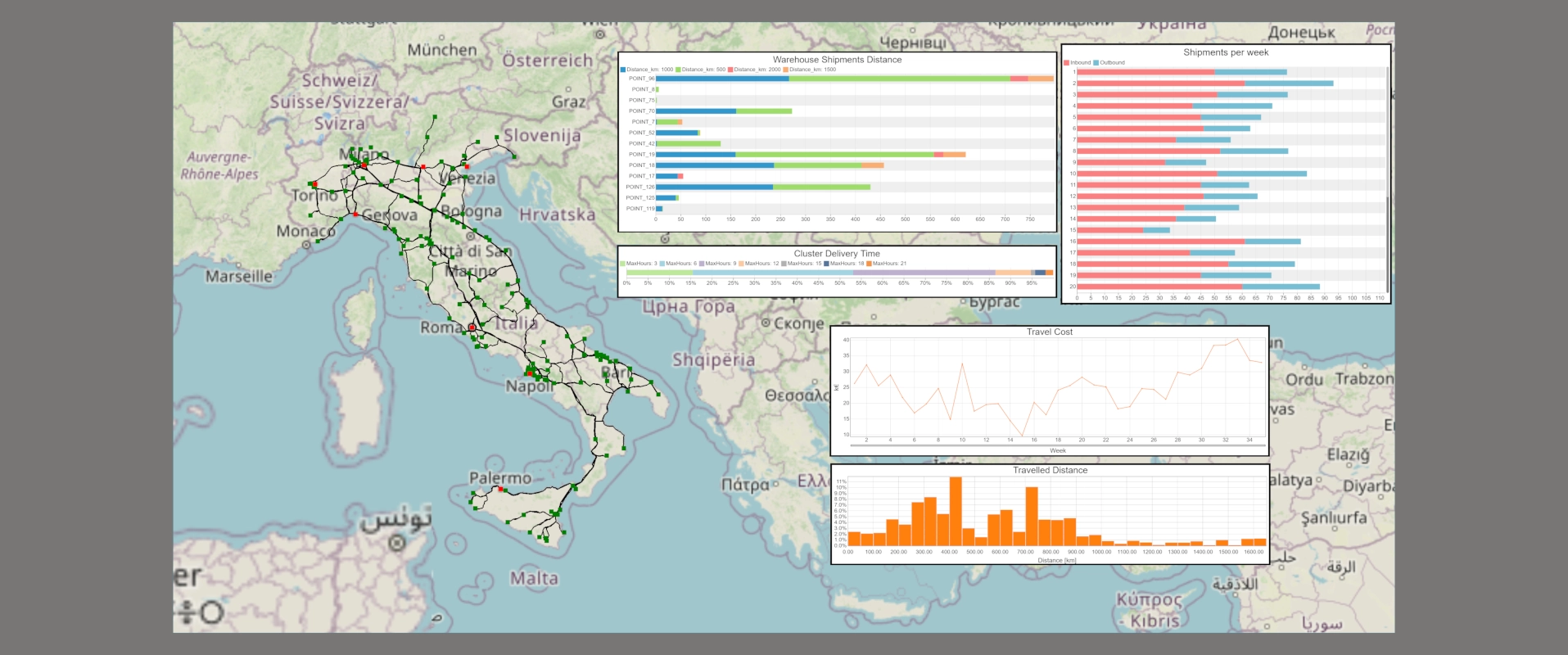

Automatic Guides Systems (AGV) Simulation

AGV system accurate design might become very complex with path constrained network, several pickup and drop-off points, many vehicles travelling within the same network. Simulation helps greatly on defining with detail all the system behaviors, including vehicle speeds, acceleration and loading constrains, battery recharging cycles as well as path networks layout characteristic, speed and direction limits, special traffic control and routing rules. FlexSim AGV module provide an easy, fast and effective way on modelling real-world AGV system of any scope or complexity level. The module employs a unique set of objects to quickly set up a fully-customizable AGV network, and utilizes familiar concepts and terminology.

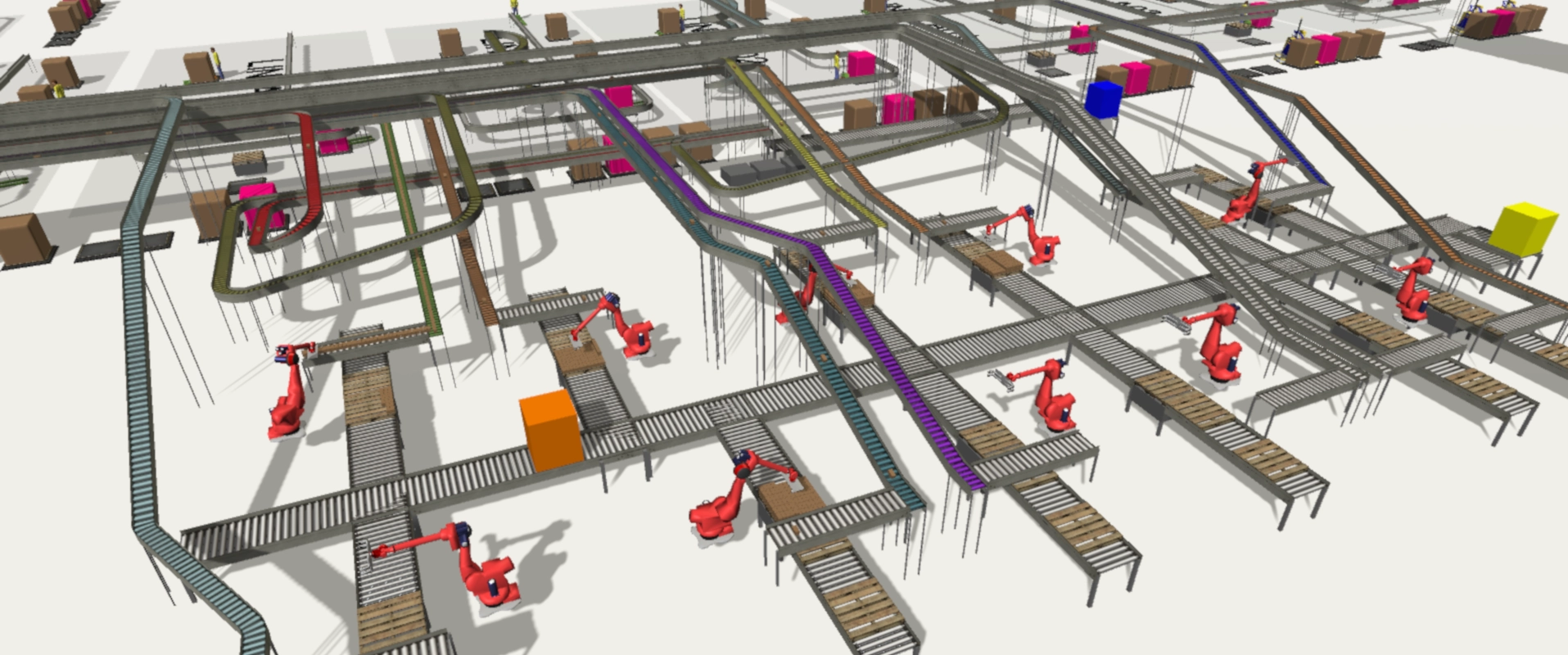

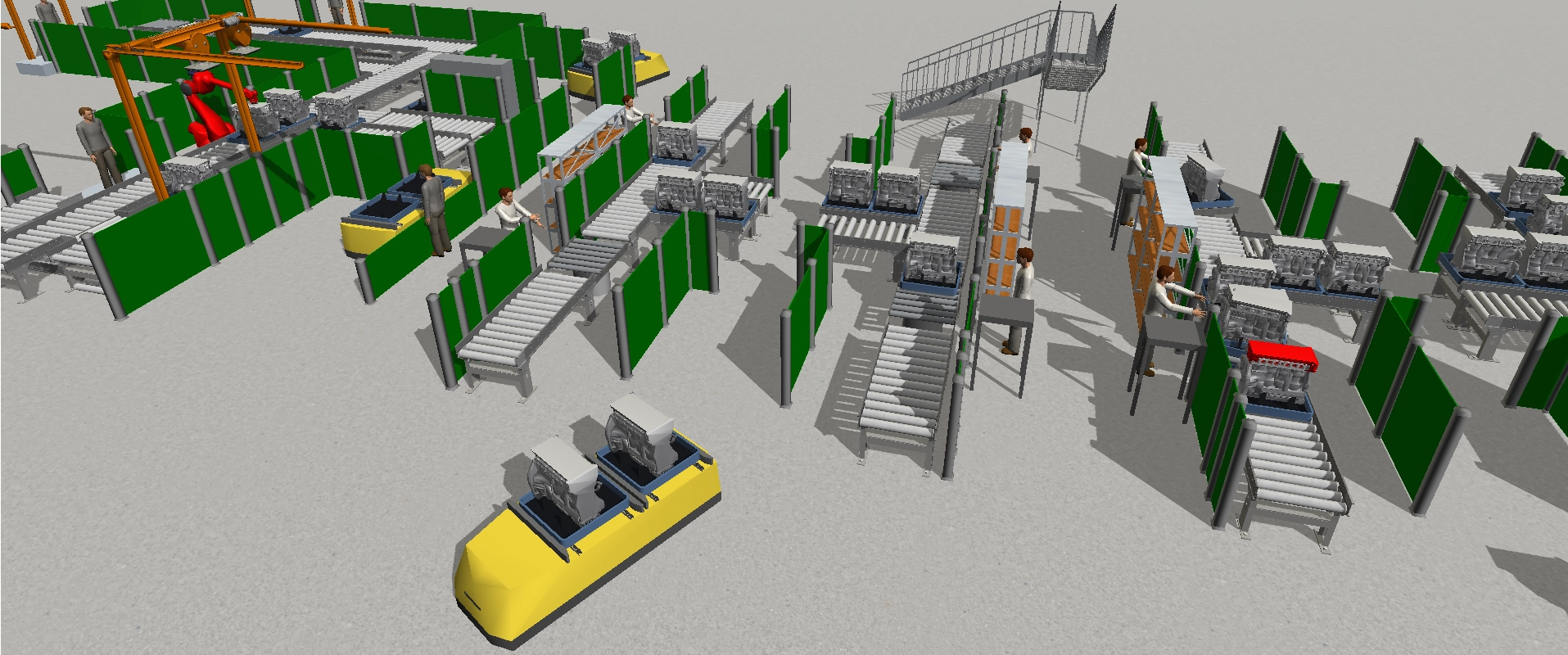

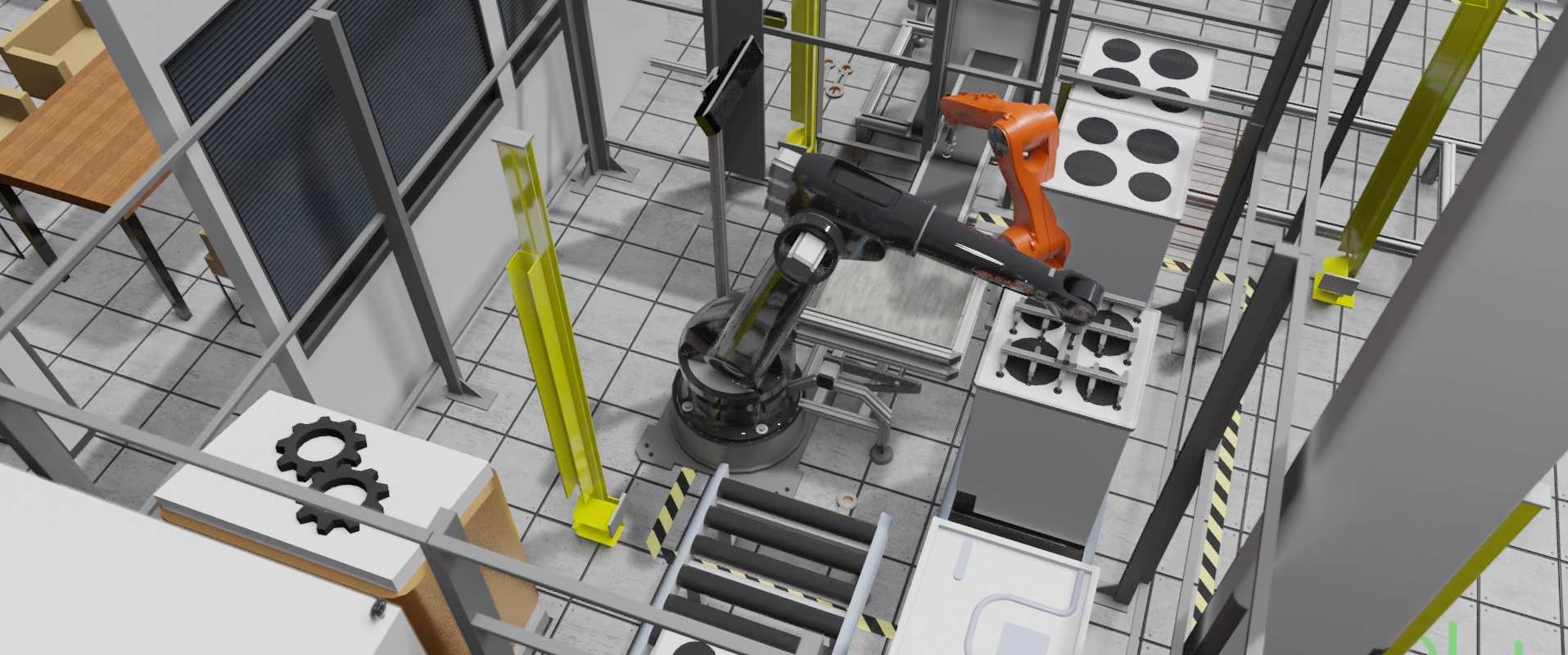

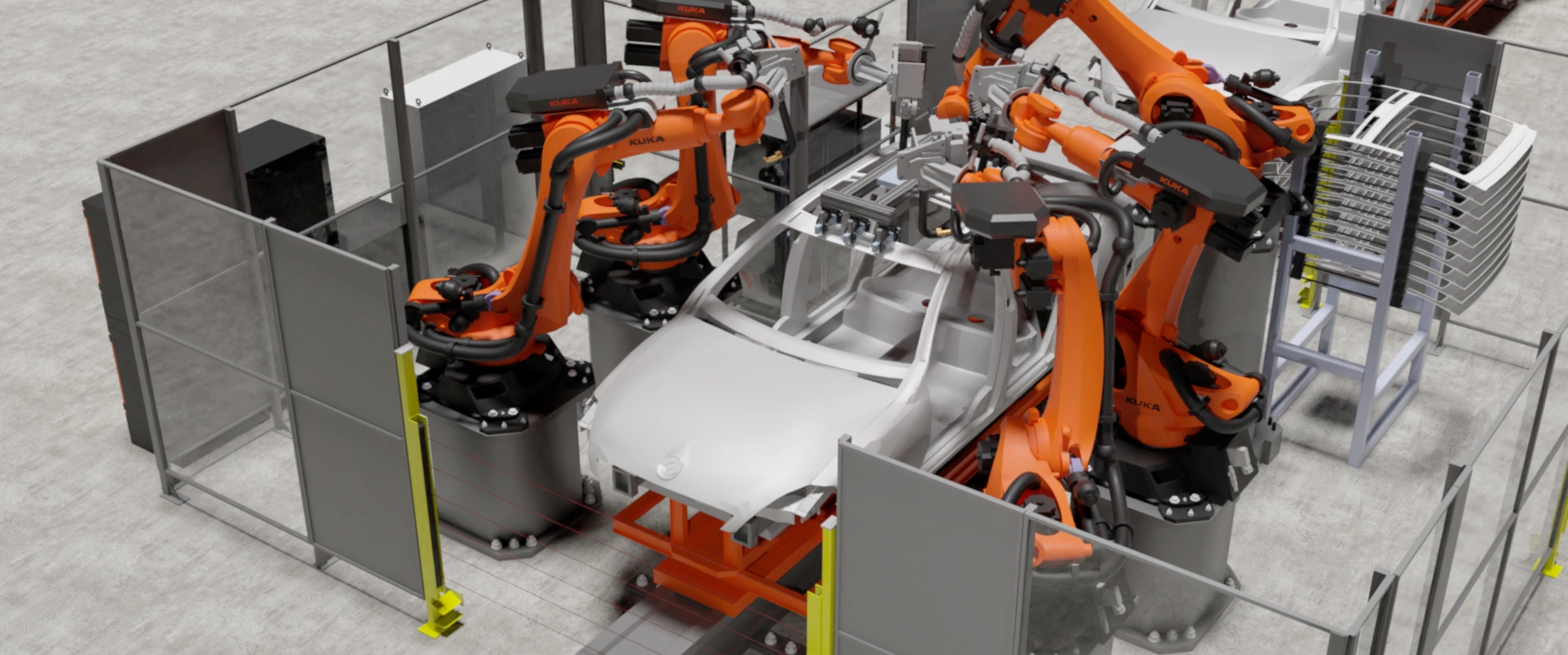

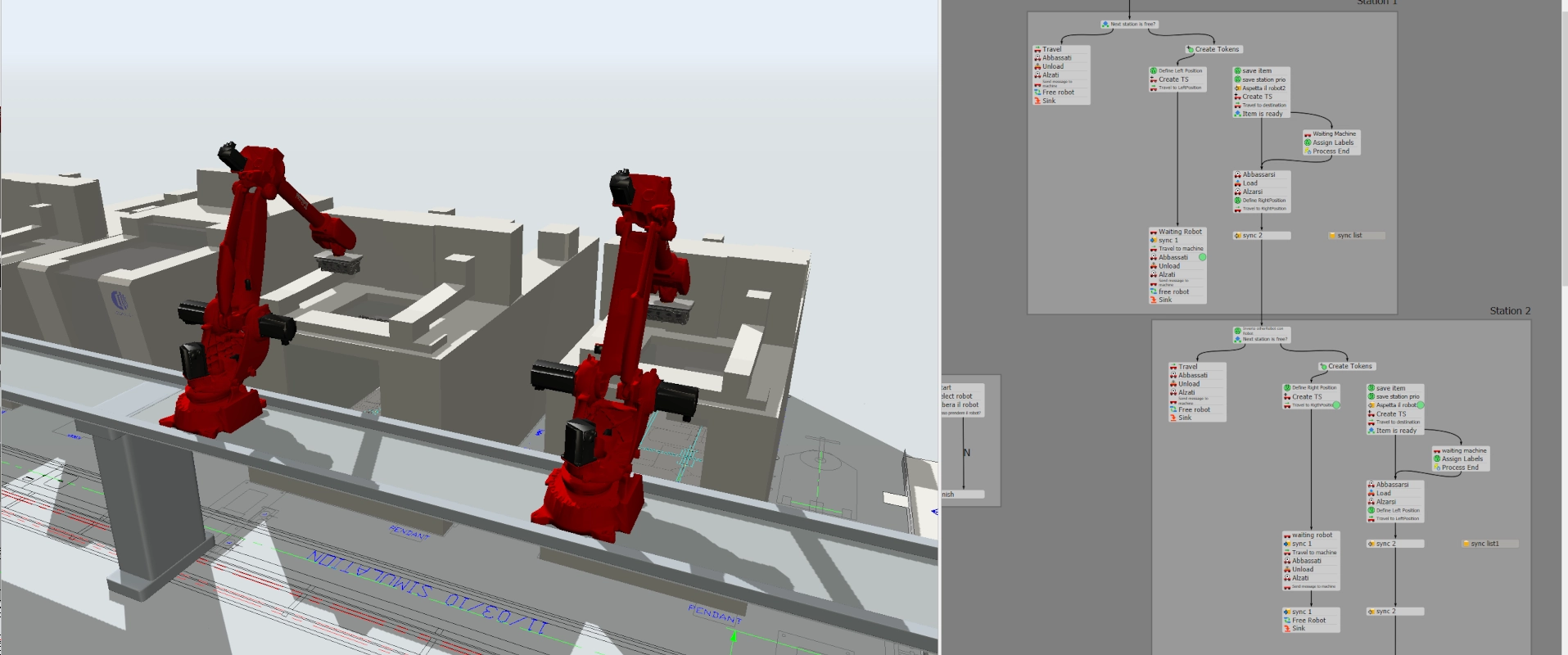

Robots Simulation

Visual Components provides an integrated working environment able to simulate any programmable manipulator used for material handling, including manipulating tools. Its simulation platform has an accurate realistic 3D simulation and kinematics engine that allow accurate robot’s motion planning, predicting precisely trajectories, cycle times and collision detection between layout’s components. Visual Components extensive material handling component’s library allow a quick layout creation and verification.