Ensuring success of manufacturing projects: a guide to smart simulation & planning

Imagine a world where every manufacturing project unrolls with precision, where production lines vibrate in harmonious perfection and last-minute chaos is a relic of the past. This is not an episode out of some sci-fi movie, but the realistic outcome achievable today through meticulous planning and cutting-edge simulation technologies. Here, in this short guide to ensuring the success of manufacturing projects through smart simulation and planning, we explore how these elements are the backbone of successful manufacturing projects from automotive to electronics and many others.

Projects aren’t successful by mere chance but are engineered to succeed right from the start. Let’s delve into the strategic planning and advanced simulations that pave the way for a seamless, error-free production process—surpassing current standards of manufacturing excellence.

The Critical Role of Planning

At the heart of any successful manufacturing project lies a well-thought-out planning phase. This phase is the blueprint from which all manufacturing strategies are developed. Planning includes an analysis of the requirements of the project, allocation of resources, assessment of potential risks, and setting up the timeline. Perfect planning makes sure it is protected from any kind of possible fail and assures smoothness and effectiveness in operating the project.

Key Planning Strategies:

- Resource Allocation: Proper allocation of resources, including manpower, materials, and machinery, ensures that projects are not delayed due to shortages.

- Risk Management: Identifying potential risks and developing mitigation strategies can prevent costly setbacks.

- Timeline Scheduling: Detailed schedules help coordinate various project phases, ensuring that each segment progresses without delay.

Manufacturing Simulation: A Game-Changer

Manufacturing simulation is a game-changing tool in industrial operations. It provides a virtual model of the production process, which allows the visualization, analysis, and optimization by engineers and project managers of the workflow without developing a physical proof and without the need for trial and error

How Does Manufacturing Simulation Work?

Manufacturing simulation consists of a precise digital replication of the manufacturing process down to the machinist operations, worker actions, and product assembly lines. This simulation allows for:

- Visualization: Teams can see the manufacturing process in action before it is implemented, helping to identify any potential issues in workflow or design.

- Optimization: It provides data on process efficiency, allowing managers to tweak and optimize various elements such as machine placement and operational sequences.

- Validation: Simulation validates the manufacturing process against the designed parameters, ensuring that the system operates as intended before full-scale production begins.

Benefits of Manufacturing Simulation:

- Reduced Time to Market: Accelerates the design and development phases, allowing for quicker project completion.

- Cost Efficiency: Identifies costly errors in the planning phase, reducing the potential for expensive corrections during physical implementation.

- Enhanced Product Quality: Ensures product quality by allowing for adjustments and optimizations before the manufacturing process begins.

Integration with Industry 4.0 and Beyond

Especially in the context of Industry 4.0, where digitization and interconnectivity of factories are the main intentions, manufacturing simulation is a matter of fact necessity. Therefore, other Industry 4.0 technologies of IoT devices designed to improve informed decision making and efficient operations with advanced analytics work perfectly with simulation tools.

Future Trends:

- Industry 5.0: As we move towards Industry 5.0, the role of simulation will expand to include more human-centric approaches, focusing on customizations and enhancements in human-machine interactions.

- AI Integration: Artificial intelligence can further enhance manufacturing simulations with predictive analytics and more advanced decision-support systems.

Case Studies and Success Stories

Manufacturing simulations have already proven their value in several industries. In its elbow-to-elbow experience with major Italian industrial companies, Flexcon has often come across excellent examples. For instance, an automotive company that used simulation to optimize the screw tightening process in assembly lines, achieving consistent cycle times and increased productivity. Another example is a large food packaging company that used simulation to automate and refine its palletizing process, dramatically reducing cycle times from minutes to seconds, and being able to simulate its packaging lines to potential buyers of its systems. Stay tuned to learn about Flexcon‘s top business cases for success.

The success of a manufacturing project must be optimized not only with quality raw materials and machinery, but also by reaching the point of operation through strategic planning and simulations. Manufacturing simulation, endorsed by manufacturers, makes it possible to predict probable problems, optimize the process and increase the level of productivity, thus making manufacturing projects a success. This area, with the development of digital technologies, will increase its impact in the near future to become an essential tool for the manufacturing industry.

Best practices for effective manufacturing simulations

Integrating simulation into the manufacturing process is a critical step for optimizing both existing and new production workflows. It demands significant technological investment, but the benefits in operational cost reductions, organizational efficiency, and training are profound.

Here we outline some of the best practices derived from extensive industry experience in dynamic production simulations:

1. Clearly define objectives and problems

Before diving into the simulation, it’s essential to define what you aim to achieve and the specific problems you’re addressing. Whether it’s reducing cycle time, minimizing resource wastage, or streamlining logistics, a clear set of objectives guides the simulation process effectively.

2. Develop a conceptual model

Construct a conceptual model that simplifies the real-world process into manageable elements. This model serves as the blueprint upon which the entire simulation is built. It should capture the essential components of the manufacturing process, including workflow, resources, and interactions.

3. Validate the conceptual model

Validation ensures that the model accurately reflects the physical process it represents. This step is crucial for building credibility in the simulation results and should involve checking for logical correctness and verisimilitude with actual production scenarios.

4. Collect and analyze input data

The quality of a simulation is highly dependent on the input data. Collect precise and comprehensive data about the production environment, including machine capabilities, worker efficiency, and material properties. This data must be analyzed to ensure it supports the objectives identified in the first step.

5. Translate into a mathematical model

Transform the conceptual model into a mathematical framework that can be simulated. This step involves defining mathematical relationships between different elements of the process, incorporating stochastic parameters to account for variability and uncertainty in production.

6. Calibration and validation

Once the mathematical model is established, it must be calibrated to reflect real-world conditions accurately. This might involve adjusting the model parameters based on historical data and validating the model by comparing its output against known data.

7. Design and execute simulation experiments

Plan and carry out a series of simulation experiments. This involves setting up different scenarios to test hypotheses about improvements and adjustments in the production process. Each scenario should be designed to yield insights that can lead directly to actionable improvements.

8. Analyze output data

Finally, analyze the data generated by the simulations to assess performance under various conditions. This analysis will reveal strengths and weaknesses in the process, guiding further tweaks and improvements.

9. Implementation of results

Translate the successful simulation scenarios into real-world applications. Implement the changes in the manufacturing process as identified through the simulation to realize improvements in productivity, quality, and cost-efficiency.

Tools and technologies

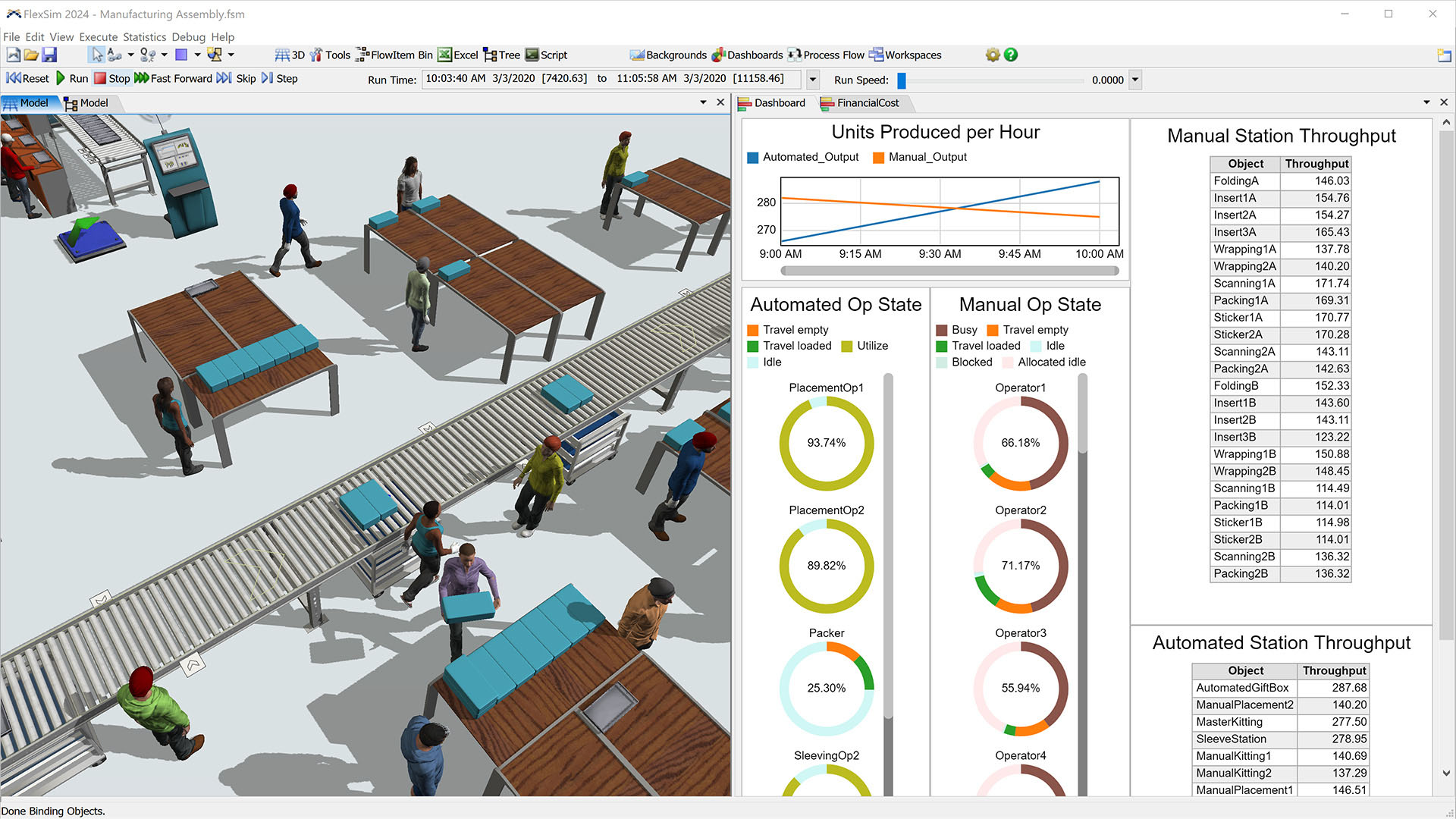

Utilize advanced simulation software and technologies such as FlexSim and Visual Components which offer robust environments for experimentation, analysis, and visualization. These tools can handle complex simulations, including those involving digital twins and cyber-physical systems, which are crucial for integrating Internet of Things (IoT) technologies.

By adhering to these best practices, manufacturers can leverage simulations to predict outcomes, plan effectively, and execute manufacturing processes that meet the modern demands of speed, efficiency, and adaptability. This proactive approach is vital in an era where production complexity and technological integration are ever-increasing.

From the macro to the small

In simulating an entire factory or industrial process, it is necessary to always move from imagining first the strategy, then the tactics: that is, first the global and macro-level operations, and only then the intricate and micro-level details. This step is critical because it allows manufacturers not only to visualize the entire production line in broad strokes, but also to zoom in on specific components and interactions, without losing sight of their focus.

Reconciling a view of the process as a whole with a granular focus helps identify inefficiencies and potential failures at the smallest levels, which are often the catalysts for broader operational challenges.

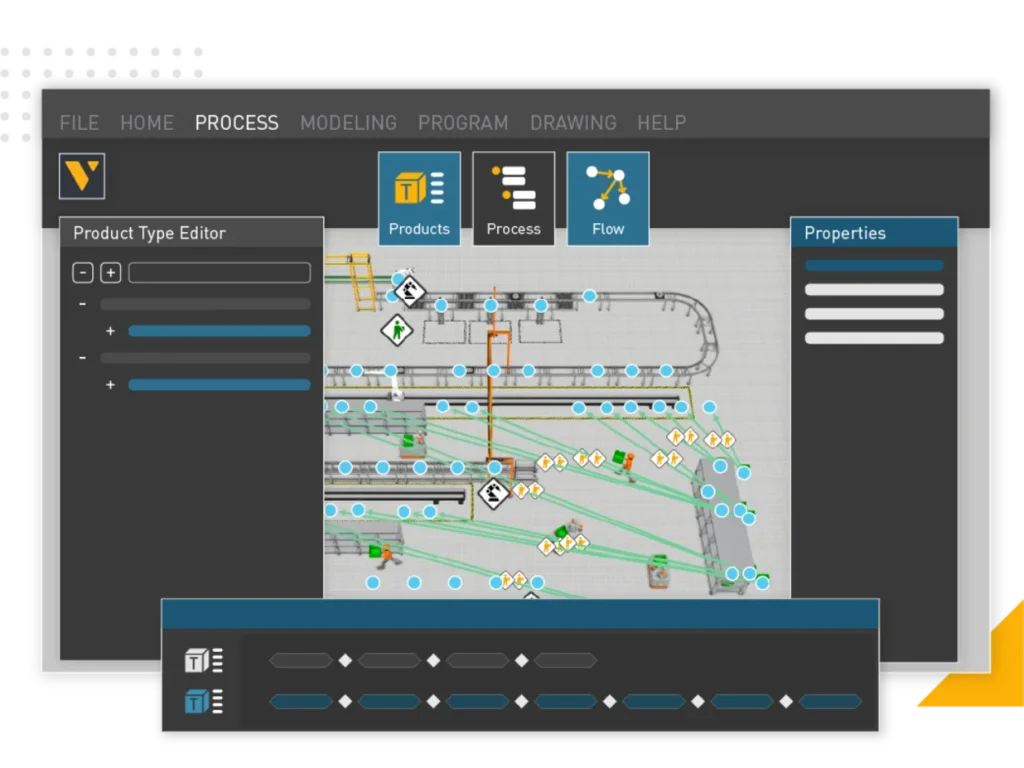

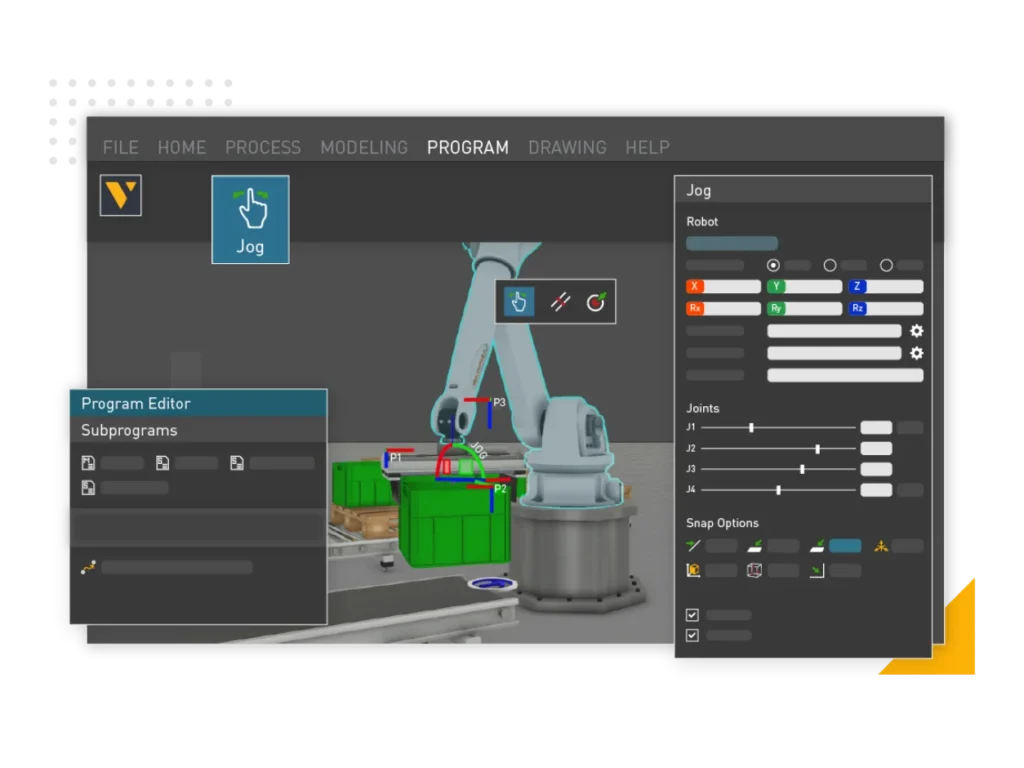

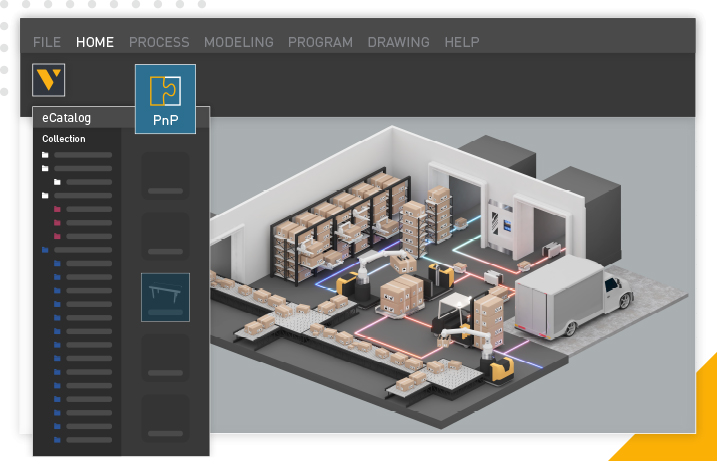

Visual Components is an advanced simulation software that expertly navigates the transition from macro to micro perspectives in industrial processes. At the macro level, it enables users to model and visualize entire production workflows, providing a broad overview of operations and allowing for strategic planning and optimization. This includes layout configuration and throughput analysis, essential for understanding how different parts of the system interact and influence overall productivity.

On the micro scale, Visual Components delves into the detailed 3D modeling and simulation of specific pieces of machinery, such as robots. It offers tools to simulate the individual functions and movements of these machines within the production line. This level of detail is crucial for troubleshooting specific operational issues, optimizing machine performance, and ensuring seamless integration into the wider workflow. By bridging the gap between large-scale process management and fine-grained mechanical simulations, Visual Components provides a comprehensive toolset that enhances both the design and execution of industrial operations.

Contact Flexcon: discover how to test and refine your real production strategies in a virtual environment.

Leveraging 3D simulation in warehouse optimization and automation for sustainability and Industry 5.0

Moving from the Industry 4.0 to the Industry 5.0 revolution transcends manufacturing and logistics to a completely different pardigm: integration with new advanced digital technologies to become more effective, sustainable and, above all, human-centered systems.

This evolution sees 3D simulation as a pivotal tool in the sustainable evolution of warehouse automation, particularly in the context of Industry 5.0 warehouse operations. It helps reduce waste, lower expenses and smooth the digital transition so that both employers and employees can profit from it.

The role of 3D simulation in optimizing warehouse operations

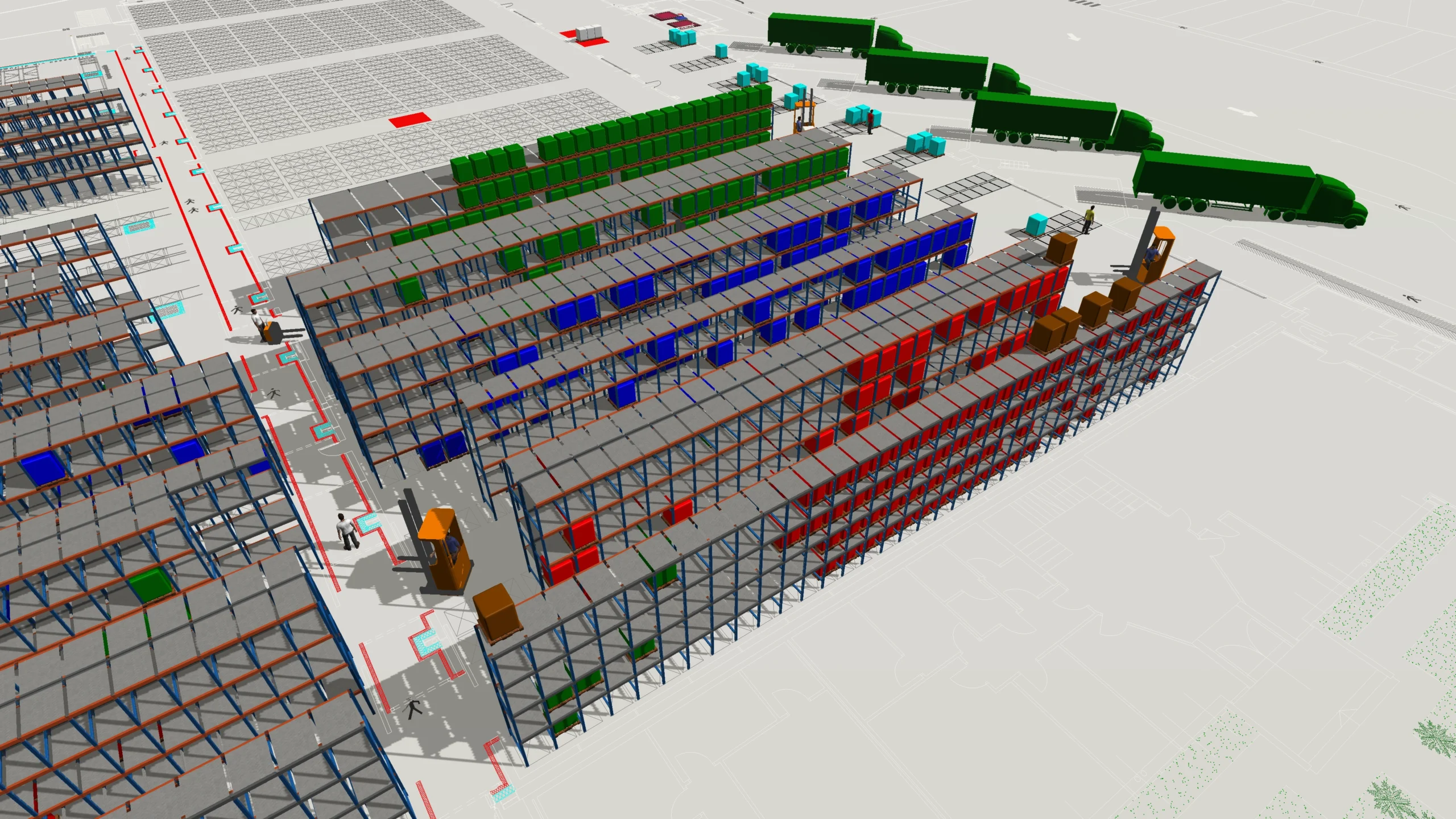

3D simulation in warehouse settings primarily focuses on optimizing layouts, streamlining operations, and predicting system performance under various scenarios. By creating virtual models of warehouse setups, businesses can test different configurations to find the most efficient arrangement of equipment and storage solutions. This proactive approach minimizes the need for physical prototypes and trial-and-error testing, significantly cutting down on waste and associated costs.

Sustainability through strategic design and resource management

One of the greatest benefits of using 3D simulations is the visualization and optimal utilization of energy efficiency in warehouse operation. For example, simulations can be of use in optimizing the placement of solar panels on the building’s rooftop or even designing a natural ventilation system with minimum demands on artificial cooling. The 3D simulation further reduces energy and machinery wear by optimizing routing and loading for AGVs and robots, respectively, consequently offering equipment life.

Expanding on these applications, 3D simulations also offer several other advantages:

- Safety enhancements: By simulating different emergency scenarios, such as fires or equipment failures, simulations help in designing safer evacuation routes and safety measures, which in turn minimize potential risks to human operators.

- Workflow optimization: Detailed simulations allow managers to see how new workflows might interact with existing processes. This is particularly useful for integrating IoT devices and automated systems, ensuring they enhance productivity without disrupting ongoing operations.

- Inventory management: Simulations can predict how changes in inventory levels affect space utilization and accessibility. This foresight helps in maintaining optimal inventory levels, preventing both overstock and stockouts.

Each of these applications of 3D simulation plays a crucial role in making warehouses more efficient, adaptable, and aligned with the sustainability goals of modern industry.

The strategic value of 3D simulation in automated warehouse forecasting

3D simulation offers a powerful means to predict the behaviors, durability, sustainability, and operational performance of automated warehouses. This technology enables businesses to foresee how automation systems will perform over their lifecycles, identifying potential challenges and optimization opportunities before physical implementation. Durability forecasts help choose robust materials and constructions that last longer and perform better. In terms of sustainability, simulations can evaluate the environmental impact of various configurations, optimizing energy use and reducing carbon footprints.

Performance analysis is particularly crucial as it determines the most efficient ways to move goods, ensuring operations are not only fast but also sustainable. Through such predictive capabilities, businesses can maintain competitive operations and adapt seamlessly to future technological advancements in warehouse management.

Enhanced decision-making and predictive maintenance

The predictive capabilities of 3D simulations enable the warehouse operators to foresee and avoid possible disruptions before they occur. With such foresight, downtime and maintenance costs are significantly reduced, and hence, not only a cut in expenses but an associated reduction in environmental impact from repairs and replacements. Predictive maintenance ensures that equipment always works at its peak efficiency and hence saves excess power consumption of the resources.

Supporting employee well-being in Industry 5.0

With Industry 5.0, the focus shifts towards a more balanced collaboration between humans and machines, aiming to enhance rather than replace human labor. A significant contribution of 3D simulation is through safe and ergonomic work environment design. This technology helps in modeling human interaction with the machine to ensure that the automatons support the human worker without causing unnecessary psychological or physical stress. Employees who feel valued and know their work is meaningful are more productive and engaged, guaranteeing a better workplace culture that initiates change and innovation.

Incorporating 3D simulation into warehouse management not only resonates with the principles of Industry 5.0 but also fosters sustainability through low waste and high efficiency. As industrial evolution continues, such technologies will be key in transitioning towards smarter and more sustainable operations that do not only prioritize the progression of technologies but rather the human factor.

Contact Flexcon: discover how to test and refine your real production strategies in a virtual environment.

Simulation: a key strategy for cost reduction and sustainability enhancement.

In pursuing genuine sustainability, enterprises must recognize the imperative to achieve long-term profitability, rather than mere surface compliance. Accordingly, it is essential to adopt, as part of best corporate practices, a consistent cost reduction and sustainability strategy along with other corporate initiatives. These may include optimizing resource use, implementing environmentally and economically sustainable processes, and adopting waste and energy reduction policies. Only by integrating these practices can we effectively track expenses and make the best use of corporate assets.

With a view to real sustainability (and not just on paper), it is increasingly important for enterprises to identify themselves as long-term sustainable entities.

Amid global market fluctuations, cost volatility has a direct impact on corporate expenses. In such a complex industrial scenario (especially in manufacturing and logistics), success depends on minimizing waste and maximizing profitability. The digital transition is key to mitigating these challenges by integrating smart manufacturing solutions, complicit with incentives for the development of smart factories, influenced by the principles of Industry 4.0 and Industry 5.0.

In all these cases, technology steps in to find possible solutions and improving operational efficiency.

Therefore, to truly lighten their footprint on the environment and society, as well as their own profits, companies must adopt practices that prioritize sustainability. However, it is clear that many European companies have yet to appreciate how technology can facilitate this effort.

Digitizing business practices and minimizing the related physical activities inherently leads to cost savings and progress toward sustainability.

Regarding our case, the Flexcon business case, within decades of working experience, process simulation has proven to be an iconic example of this phenomenon.

Simulation emerges as a powerful tool in the quest for sustainability and cost reduction. By accurately modeling various scenarios, companies can identify inefficiencies and optimize resource utilization without the need for time-consuming physical experimentation, as was the case in the past.

Digitization and key cost reduction strategies: the spotlight on virtual simulation

According to the 2023 Technology Leadership Deloitte study, companies should intensify the use of digital technologies to implement virtuous practices in all business processes.

Partly due to implementations with AI and state-of-the-art technologies, simulation comes to the rescue in many areas, with different goals and operational tactics.

For example, to achieve greater supply chain visibility, improve productivity, monitor and optimize energy costs (including in the context of new Industry 5.0 directives), and strengthen connectivity with stakeholders and consumers.

The following are a few examples.

Supply chain optimization

- Material flow simulation: Simulation allows the flow of materials throughout the supply chain to be modeled and analyzed in the perspective of a cost reduction strategy. This helps identify potential delays, inefficiencies or trouble spots that could compromise the supply chain.

- Production planning: Using advanced simulation models, companies can run predictive simulations based on future demand. This allows them to optimize production and supply planning, avoiding situations of overproduction or inventory shortages.

- Stock management: Logistic simulation enables “what-if” scenarios to be run to determine the optimal stock level. This helps minimize excess inventory while reducing associated costs.

Enhancement of productivity

- Production line simulation: by modeling the entire production line, inefficiencies, downtime and bottlenecks can be identified. This allows targeted improvements to be made to optimize workflow, reaching kpi and thus increasing overall productivity.

- Production planning: simulation allows different production planning strategies to be tested. This includes evaluating optimal shifts, resource allocation and priority management, helping to maximize operational efficiency.

Reducing the impact of energy costs

- Process optimization: through virtual simulation, the company is able to detect the inefficiencies within the production process. Consequently, it can develop strategies to reduce energy consumption, which helps to contain the impact of energy costs on production and in operations in general.

- Risk and opportunity Management: companies can use virtual simulation to assess the real-world impacts of energy price fluctuations. They can also develop action plans to both mitigate risks and to capitalize on opportunities in the global energy market.

- Additional modules to simulate power consumption: in addition to basic functionality, simulation software offers additional modules (add-ons) specifically designed to simulate and optimize energy consumption, enabling companies to further improve energy management and reduce energy-related costs.

Strengthening Connectivity

- Digital connectivity simulation: simulation models enable the assessment of the impact of technology solutions such as the Internet of Things (IoT) and cloud connectivity on supply chain and operations. This encourages greater interaction between devices and systems.

- Virtual collaboration: simulation can facilitate collaboration with suppliers, partners and other stakeholders. For instance, by providing hands-on visualization of processes, which facilitates meaningful understanding by all stakeholders. In a participatory session, parties can examine the flow of activities together and discuss specific details with more clarity than a purely speculative description. Simulation also facilitates standardized benchmark conditions, ensuring that all involved parties encounter the same variables and circumstances. This eliminates possible bias in the results and provides a fair basis for comparison.

Reduced footprint

- Reduction of those costs that are a result of space utilization: reducing the space occupied by facilities can lead to a reduction in costs associated with renting or purchasing land, as well as a reduction in operating costs associated with the management and maintenance of the facilities.

- Impact on process speed: efficiencies resulting from more compact layouts can lead to higher productivity and reduced production costs. Therefore, integrating footprint reduction as part of a cost reduction strategy can contribute significantly to overall business efficiency improvement.

In pursuit of cost reduction, it is critical to adopt advanced practices. This will not only enable more efficient operations, but also spur innovation and growth. Among the many best practices available, process simulation emerges as a key enabler for thoroughly understanding each stage of production. This is just the first step toward smarter, quality-driven cost management.

Errors to avoid

People often misunderstand the concept of “cost reduction. It is crucial to be aware of the obstacles that could undermine our efforts. Cost reduction is not synonymous with making indiscriminate cuts, which can instead lead to compromises on quality and efficiency in the long run.

The true essence of cost reduction lies in optimization, not sacrifice. It involves a thorough analysis of business processes. The aim being to identify inefficiencies and waste to improve overall efficiency without compromising quality. A cost reduction strategy, if properly undertaken, becomes a means to achieve smarter resource management. In addition it promotes the long-term sustainability of the company.

We briefly present here an overview of the most common mistakes to avoid. The path to real efficiency must be as smooth as possible.

- Linear cuts: making indiscriminate cuts without careful analysis can damage product quality and reduce customer satisfaction. Budget reductions should be strategic, focused on non-vital areas, and supported by a detailed assessment of the impact on critical processes.

- Ignoring emerging technologies: resisting the adoption of innovative technologies can lead to a competitive gap. Investing in advanced solutions, such as automation and IoT, not only improves operational efficiency but can generate long-term returns, ensuring competitiveness in the changing industrial landscape.

- Underestimating employee engagement: Ignoring the importance of employee engagement can generate a negative work climate. Active staff involvement is essential to implement effective changes, improve productivity and promote a positive work environment.

- Failure to analyze risks: Ignoring risk assessment can result in unforeseen costs. Careful planning, including an analysis of potential risks, prevents future problems. It also ensures that we make decisions as a result of accurate up-to-date data.

- Failure to update knowledge and technologies: Ignoring the importance of keeping knowledge and technologies up-to-date can have significant consequences. We live in an ever-changing international landscape. Gas and energy costs are rising, and knowing available alternatives is essential. Maintaining a constant focus on calls and opportunities to acquire tax credits or other forms of credit is critical. In addition, knowledge and integration of simulation as a business technology asset can optimize processes and reduce costs efficiently.

Process simulation is a familiar practice for many, a game-changer for everyone in the manufacturing community.

In pursuit of an effective cost reduction strategy, the integration of process simulation is a key requirement. However, it is pivotal to avoid mistakes and adopt a strategic approach to ensure success in achieving cost reduction goals.

Contact Flexcon: discover how to test and refine your real production strategies in a virtual environment.