A Simulation of Dynamic Assemblies and Flexible Packaging with FlexSim

The dynamic management of assembly and packaging processes in multi-product and complex logistics scenarios requires tools capable of adapting to variable component mixes and frequent production changes.

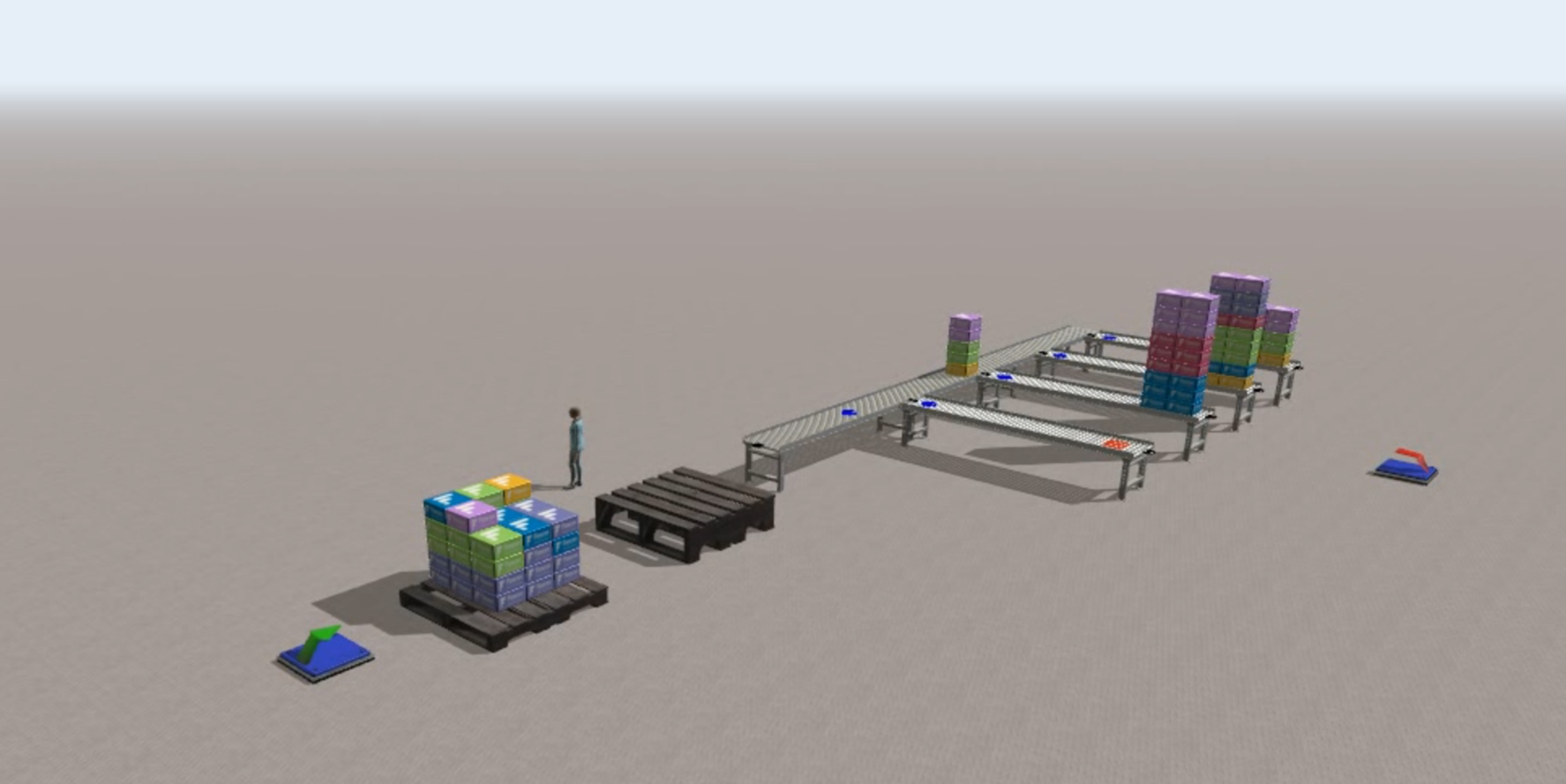

With FlexSim, we developed a custom object that realistically simulates this behavior: starting from a simple queue, we assigned it a completely new purpose and advanced functions typical of a combiner — all without writing a single line of code.

The challenge

In many real-world processes, a machine or packaging line needs to:

- combine different parts in variable proportions to create finished products

- quickly switch between different assembly configurations

- respond opportunistically to the availability of components, without rigid setup constraints

The standard Combiner in FlexSim is not designed for these dynamic scenarios, as it works with fixed parameters. A more flexible solution was therefore needed.

The solution: a queue object with combiner logic

Our solution started from a standard queue object. By using an object-type Process Flow and a configuration table, we assigned this object:

- control logic to check the availability of required parts

- the ability to combine components into variable configurations

- dynamic flow management, without manual interventions in the model

This architecture allowed us to transform a simple queue into an advanced component capable of:

- continuously monitoring the availability of parts

- creating finished products as soon as all required components are present

- alternating between different types of products within the same production flow

How it works

The system is based on three main elements:

- 1. Object-type Process Flow

Assigns logic to the queue object to manage the picking and combination of parts. - 2. Configuration table

Defines, for each product, the list of required components and their quantities. - 3. Token for each product

Each token represents a product to be created and knows the list of necessary parts.

Operational flow: step by step

- All components enter an input queue.

- The tokens compete to collect the required parts from the queue.

- When a token has gathered all the necessary parts, it moves them to the next queue and forms the finished product.

- If parts are missing, the token waits until they become available.

Code-free flexibility

One of FlexSim’s most powerful features is the ability to:

- model custom logic using Process Flows

- personalize object geometry to improve 3D visualization

- do all of this without writing any code, thanks to intuitive visual tools

For example, in our model the queue was also graphically modified to appear as a pallet. This makes the simulation not only functional but also visually clear for analysis and presentations.

Strategic insights: practical applications

This solution can be applied to:

- packaging and logistics companies that need to fill containers or pallets with variable product mixes

- warehouses and packaging centers that prepare kits or assorted boxes

- multi-product production lines that alternate configurations without stopping production

- analysts evaluating dynamic flows to optimize resources and reduce bottlenecks

Video: full queue customization

Watch how we transformed a simple queue object into an advanced component with combiner logic and customized geometry.

Try the model

If you are already a FlexSim user, you can contact us to receive the model and test it directly in your simulation environment.

📩 Write to marketing@flexcon.it the receive the model file for free.

Don’t have FlexSim? Try it for free!

If you’re not yet using FlexSim, you can download the Express version, free of charge. It comes with some limitations but still allows you to run the model.

Download it ➡ here.

You can also visit the forum https://forums.autodesk.com/t5/flexsim-forums/ct-p/flexsim-en for this and other useful models!

Contact Flexcon: for a complete demo of all FlexSim features.