Emulation for FlexSim: Testing Automation Without Risks

In industrial automation, every plant must operate precisely and reliably.

However, testing control software directly on real machines can be risky and costly. Production interruptions, system downtime, and other unforeseen issues can cause delays and increase commissioning costs.

For this reason, companies worldwide have already adopted Emulation for FlexSim, an add-on developed by Flexcon. This tool enables testing and validation of PLC logic in a virtual environment.

By simulating machine behavior before real implementation, errors can be detected and corrected without stopping production. As a result, the commissioning process is optimized, ensuring smoother integration between control software and physical systems.

Use Case: Integration Between PLCSIM Advanced and FlexSim

A concrete example comes from Sebastian Hemmann of Ingenieurbüro für Prozesssimulation, a FlexSim distributor in Germany, based in Brunswick, Lower Saxony (www.fs-ad.de).

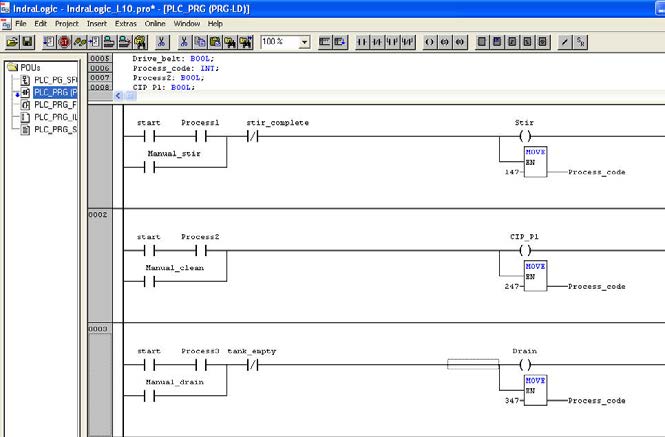

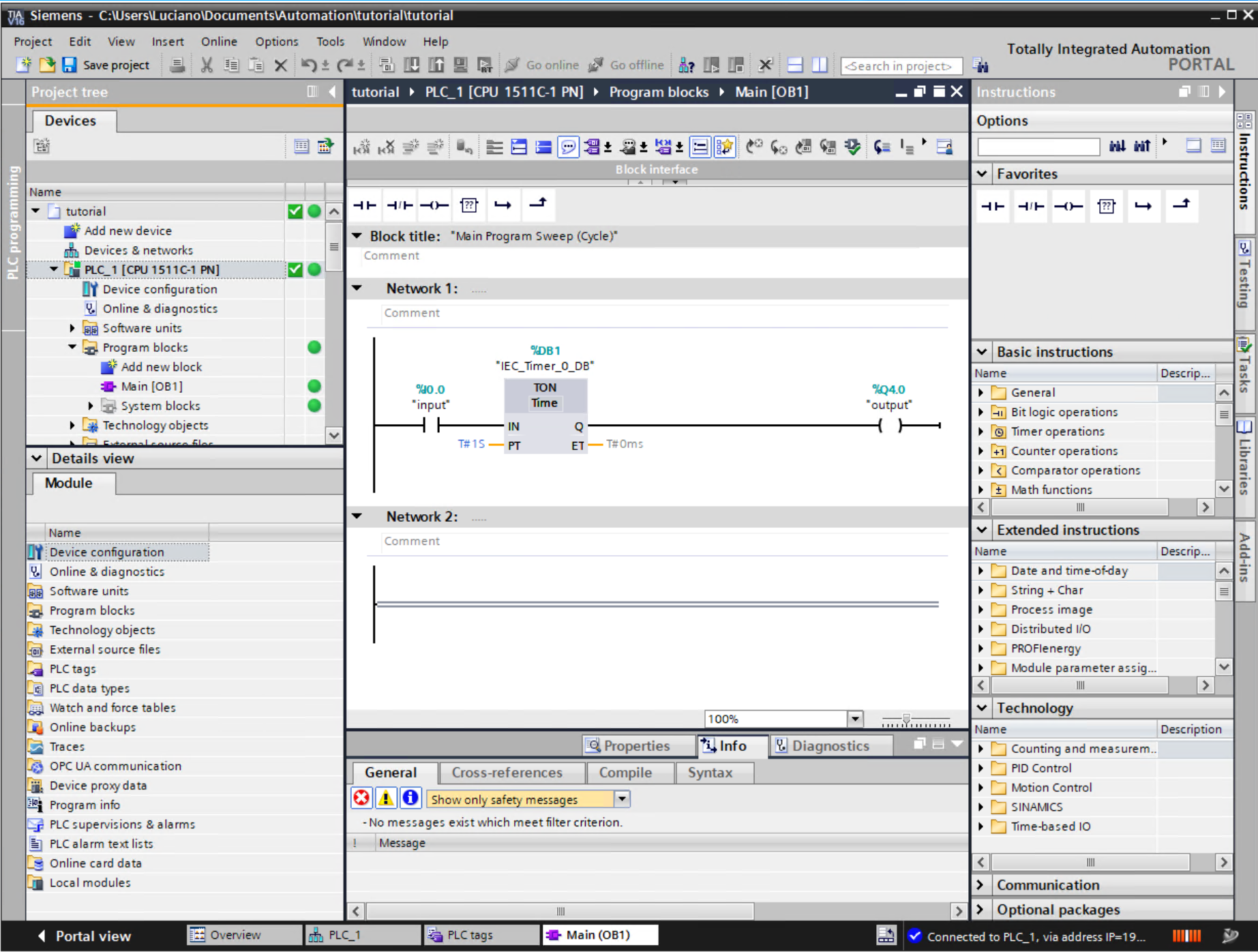

His project demonstrates the use of Ladder Logic developed in Siemens TIA Portal and simulated in PLCSIM Advanced. This logic is used to control a conveyor system modeled in FlexSim via the Emulation add-on by Flexcon. This approach makes it possible to validate PLC logic without directly interacting with the physical system.

How Does the System Work?

The system includes two chain conveyors and a bulk material conveyor belt, all controlled by PLC logic. The PLC receives input from two photoelectric sensors and a weighing scale. The system follows a precise cycle:

- Phase 1: Only one of the two chain conveyors is active.

- Phase 2: When a container blocks the first photoelectric sensor, the conveyor stops, and the bulk material conveyor activates to load the material.

- Phase 3: When the weighing scale detects the target weight, the transport stops. If the second photoelectric sensor is clear, both chain conveyors resume operation.

Thanks to Emulation for FlexSim, these steps could be tested in a virtual environment, ensuring every process phase runs smoothly without risks to the physical system.

Why Is Emulation So Valuable?

- Reduces Risks: Enables testing and optimization of control logic without affecting real systems.

- Lowers Commissioning Costs: Avoiding tests on physical machines reduces time and expenses.

- Enhances Collaboration: Facilitates cooperation between automation engineers and designers by integrating control software with realistic models.

Flexcon and Its Contribution with the Emulation add-on

Emulation for FlexSim is an advanced module that connects FlexSim with both real and virtual PLCs to test and validate control logic in realistic scenarios. It supports various protocols, including OPC UA/DA, Modbus, Siemens S7, Beckhoff ADS, and Allen-Bradley, ensuring seamless integration with major industrial systems.

Flexcon, the Italian distributor of FlexSim and developer of Emulation, provides advanced solutions to integrate simulation with industrial automation. One of our core goals is to help companies reduce costs and risks in their commissioning processes.

Beyond Emulation, Flexcon has recently developed a new add-on dedicated to sustainability and energy optimization, further reinforcing its commitment to enhancing industrial efficiency.

Thanks to these technologies, companies can transition from a digital model to a digital twin, ensuring an ever more accurate and dynamic virtual representation of production facilities.

Try FlexSim for Free

To use Emulation, you need FlexSim’s full version. However, if you haven’t tried FlexSim yet, you can start by downloading the Express version, which is free with some feature limitations but perfect for exploring the software and understanding its capabilities.

📥 Download it ➡ here.

Contact Flexcon: for more information on the Emulation module.